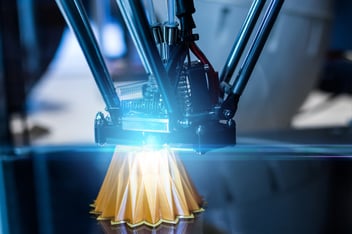

Additive Manufacturing (AM) or 3D printing is a technology whereby three-dimensional objects can be fabricated by means of the deposition of materials in subsequent layers. Its spread in industry has been steady over the past few years, thanks to constant technological evolution and decreasing costs.

Initially, one of the main areas in which 3D printing was used was the production of prototypes and smaller-scale models to test the functional characteristics of products. However, additive manufacturing is becoming increasingly important also for the fabrication of finished products, for both small batches and mass production. This is possible thanks to Additive Manufacturing’s ability to produce complex geometries that would be difficult or impossible to achieve with traditional manufacturing techniques.

In addition to the manufacture of final parts, 3D printing is also used to create production tools, such as painting templates and moulds for manufacturing plastic parts. In this case, additive manufacturing makes it possible to obtain lighter, more resistant tools than those produced using traditional techniques, as well as higher-performance objects (e.g. conformal cooling channels improve mould performance).

Additive Manufacturing is also revolutionising the medical sector, by allowing the manufacture of custom prosthetic devices and patient-specific surgical instruments. Furthermore, 3D printing is increasingly breaking into the aerospace and automotive industries, where lighter parts can help to enhance vehicle performance.

A fast-expanding overall market

The Additive Manufacturing market is growing quickly, with a global value of $16 billion (+28% YoY 2016-2020) and expansion that varies depending on the sector.

More specifically, there has been a 40% increase in the volume of VC and CVC investments (2010-2018) in companies operating in the field, with the entry of the first incumbents (such as GE and Siemens) through the acquisition of start-ups for the internationalisation of know-how.

The adoption of 3D printing is currently concentrated in specific sectors, particularly medical devices and the aerospace industry, without forgetting accessory applications for other sectors, such as spare parts and R&D prototyping. However, there is potential to apply additive manufacturing in a cross-sectoral manner and reach its full potential in 10 to 15 years through a factory model with 70% Additive Manufacturing machinery and the remaining 30% for part finishing.

Find out how to make production processes more efficient using Additive Manufacturing technology. Download our free guide!

The value of Additive Manufacturing in the main sectors

Consumer products: overall value of $1.8 Bln. In the CP sector there is growing demand for low-cost custom products, from footwear to bicycle saddles, characterised by small production cycles.

One such example comes from Adidas with the production of its new 4DFWD shoe, the result of its partnership with Carbon, a big name in the 3D printing industry.

This partnership was based on the aim of offering professional athletes footwear customised to suit their characteristics, in order to fully enhance their performance.

Aerospace: overall value of $2.5 Bln. The aerospace industry is characterised by growing demand for high-performance parts, with highly sophisticated form factories and pieces that are difficult to manufacture using CNC machinery/injection moulding. The great many objects that can be manufactured by 3D printing include the body interiors of mass-produced aircraft (which can be customised for the individual airlines), but also rocket refuelling pipes, turbine blades and components for aircraft and spacecraft engines.

Manufacturing & Automation: overall value of €2.0 Bln. We are already seeing progressive optimisation in the machinery/technology adopted, for example the production of moulds for injection moulding, and in the use of Additive Manufacturing in the production of in-line tools.

Medical Devices: overall value of $2.5 Bln. The growth in demand is strong, considering the need for higher production volumes for existing applications (e.g. prosthetics) as well as new applications (such as valves made using biomaterials).

This also addresses the need to manufacture products at locations other than where they are designed, i.e. printing parts, such as dental appliances, directly in hospitals.

Automotive: overall value of $2.9 Bln. The focus in this case is on spare parts, where it avoids the need to setup a dedicated supply chain, without forgetting the pre-production phases and, in some cases, such as the luxury car sector, the production phase.

Other sectors: overall value of $3.9 Bln. We are witnessing the first applications of 3D printing in other sectors, such as Fashion, Oil&Gas, Energy and Consumer Electronics.